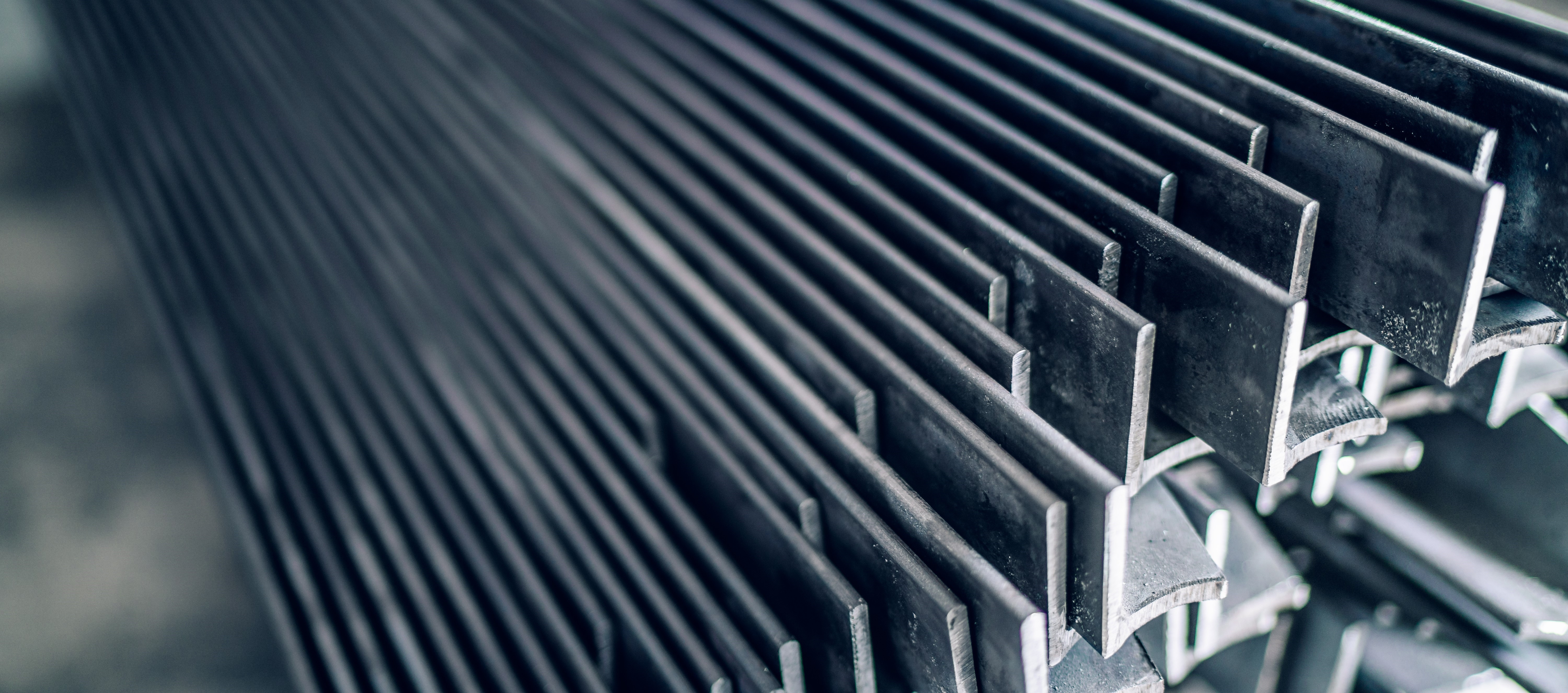

Laser cutting grants great flexibility and high cutting speed. The cutting process provides high-precision cuts, and the possibility of designing complex workpieces. There is also a minimum of heat exposure.

Laser cutting provides an incredibly high quality in the cut and allows for cutting of virtually all types of metals and alloys. As a fast and efficient cutting technique, it is competitive in small and large series alike.